Eco-Ceto plastics recycler

A couple of years ago I was musing on some of the environmental problems that our planet is currently facing, and I had a brainwave. I have long thought that sooner or later oil prices will rise high enough for it to become cost effective to break plastics down into their constituent hydrocarbons that could be used as fuel or as precursors for other chemicals.

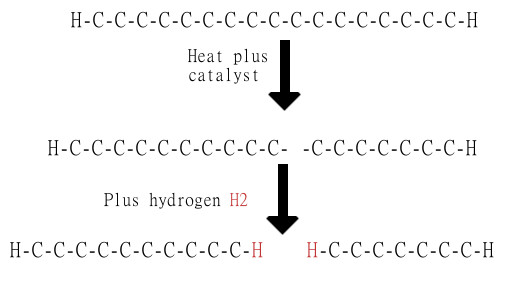

One problem with this process is that it takes a lot of energy, in the form of heat, to break those links. Another problem is that hydrogen is required - each broken link requires a hydrogen molecule (H2) to supply a hydrogen atom as an end for each of the two new chains produced. This simplified diagram shows what I mean:

It occurred to me that this hydrogen could be generated through the electrolysis of sea water, using electricity from solar or wave power. Electrolytic cells that will do this already exist (this links to a PDF document). The main byproducts of producing hydrogen are either oxygen, which could be either collected or released into the atmosphere, or chlorine, sodium hydroxide and hypochlorite. Different electrodes and cell conditions result in different products; it will undoubtedly require some experimentation to get this just right.

Sodium hydroxide reacts with carbon dioxide to produce carbonate, which is alkaline, so adding this to the oceans will alleviate the acidification of the oceans caused by increasing carbon dioxide levels. The chlorine produced (if any) will have to be stored (perhaps by chemically reacting with "an aqueous solution containing about 1 to 400 g/l of iron(II) chloride and at least one of copper (I) and copper(II) ions, the chlorine being adsorbed with conversion of the iron(II) chloride into iron(III) chloride" (United States Patent 4082631 ). Some plastics (for example PVC) also produce chlorine when cracked, so we will need a way of dealing with chlorine anyway, making the kind of electrolytic cell that produces both chlorine and hydroxide more practical.

The heat required for the plastics cracking process could also be supplied by the sun: a parabolic mirror of the right size in a sunny part of the world would be effective.

I can imagine two different ways this might work.

The first would be a small plant on a beach, perhaps on the Indian Ocean, where waste plastics are continuously washed up. Local people could supply the machine with plastics they picked up on the beach, and the machine could be set to produce hydrocarbons that would work as fuel for whatever the favoured local mode of transport might be. Fractional distillation using solar heat and seawater coolant should work. Maintenance and repairs could also be carried out by trained local people.

The second would be a floating drone plant, powered by solar energy, gathering plastics from one of the several plastic gyres in the oceans. It could also produce and store hydrogen gas, again from the electrolysis of seawater. Whether it would be feasible to have an unmanned plant cracking plastics, given the high temperatures involved, I'm not sure. Perhaps it would be better to just collect plastics and hydrogen, and send out a radio beacon message to alert the owner that it is full. The cracking process could then be carried out elsewhere.

Clearly there are several aspects of this that need clarifying, and a feasibility study needs to be done. Separating the polymers from other material such as marine life and other garbage could be a problem, as could disposing of any chlorine generated, but these are hopefully surmountable.

My back-of-the envelope calculations suggest that it could work. It would require a considerable initial capital outlay, but running costs would be minimal; cleaning, maintenance and repairs only. As oil prices continue to rise, the viability of this type of operation will only increase.

If you have any ideas as to how I can get the right people interested in this idea, please let me know - click the 'Contact' button at the top right of the page.